MAXPAC

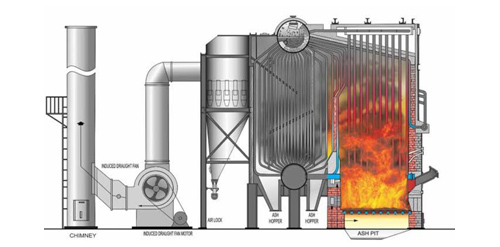

3-pass integral furnace coal /wood /brequett fired IBR Boiler, capacity upto 6000 kg/hr.

OPTIONS TO INCREASE SAVINGS

WATER PRE HEATER

AIR PRE HEATER

POLLUTION CONTROL BY MECHANICAL DUST COLLECTOR

PETROMAX

Petromax – We are indulged in providing an extensive range of petromax to the customers. These products are leakage proof and durable. The products are available in different sizes and ranges. All the products are of optimum quality, low maintenance and eco-friendly.

Features:

AGROMAX

Smoke tube – 3 pass Internal furnace husk fired IBR boiler , capacity upto 6000kg/hr

UNIQUE FEATURES

AGRIPAC

Smoke and water tube combination design external furnace, fluidised bed boiler for agrowaste , capacity 2TPH to 20TPH

WATER CUM SMOKE TUBE BOILER

SALIENT FEATURES

FUEL EFFICIENCY

AGRI PAC is designed to burn variety of fuels like wood , coal , briquettes , ground nut shell , bagasse , rice husk , and several other biomass fuel as jaliflora , cotton stalk , mustard stalk , cow dunk cakes , sunflower husk , palm kernel shell , king grass , corn cobs , soya husk olive palettes etc.

HEAT RECOVERY

To improve overall efficiency of the system further various heat recovery options available as per air pre heater and water pre heater .

LOW OPERATING COST

It ensures low operating cost due to several unique benefits that come in built with this product

MODE OF FIRING

They are provided with optimally sized firing doors for convenient feeding the fuel.

They offer pneumatic feeding option for feeding unconventional fuels like; sawdust /coal /dust/bagasse.

For higher combustion efficiency and complete combustion for petcoke and paddy husk.

Designs for the max safety and consistent steam supply.

STAINLESS STEEL NOZZLES

Extended nozzles life and life long durability.

VERTICAL FEED WATER PUMPS

Lower power consumptions and trouble free working.

MAINTENANCE FRIENDLY BOILER

They are maintenance friendly boiler quick shutdown time for cleaning is a unique plus point of boiler.

CARES FOR THE ENVIRONMENT

SAFETY FEATUREST

COMBI MAC

FACTORY ASSEMBLED BOILERS

COMBI MAC comes to you skid mounted water cum smoke tube boiler and ready to use – minimizing erection cost and site work.

HIGH EFFICIENCY

This boiler has been designed with high combustion volume – better efficiency.

FUEL FLEXIBILITY

This has been designed to burn variety of fuel like coal, wood , briquettes, ground net shell , bagasse , rice husk and several other biomass fuel .

HEAT RECOVERY OPTION

COMBI MAC has been designed to improve overall efficiency of the system further various heat recovery option are available as per air pre heater and water pre heater.

MODE OF FIRING

These boilers are provided with optimally sized firing doors for convenient feeding of fuel.

This boiler offers pneumatic feeding option for feeding unconventional fuels like ; saw dust /coal dust /bagasse. The system can also be given as supplementary system along with FBC firing.

For higher combustion efficiency and complete combustion for petcoke and paddy husk.

Designs for the max safety and consistent steam supply.

CARES FOR ENVIRONMENT

SAFETY FEATURES

POWERMAC

Water tube boiler i.e Bi-drum, single drum fluidized bed/dumping grade boiler for bagasse , agrowaste . capacity from 15 TPH to 60 TPH with working pressure upto 52kg/cm 2

UNIQUE FEATURES

EFFLUENT TREATMENT PLANTS

ETP- Manufacturing Industries like Pharmaceuticals, Textiles, Chemical etc generate effluents which result in water pollution and contamination of water. Contaminated water cannot be filtered without treatment as it contains toxic chemicals. This is the reason as to why ETP’s are being installed in most industries.

The Effluent treatment plants (ETP) are used for the removal of high amounts of organic compounds, debris, dirt, grit, pollution, toxic, non-toxic materials and polymers etc. from industrial effluent. The ETP plants use different methods and other auxiliary techniques such as centrifuging, filtration , incineration for chemical processing and effluent treatment.

AIR POLLUTION CONTROL EQUIPMENT

Every industry need to take measures to control Air Pollution. Air pollution control equipment is a vital component of industrial processes that cannot be neglected. Almost every industries send harmful stuffs to environment . Petroleum, energy production, coal and metal mining, chemical, and waste management industries are a few of the big-league players that have played a considerable role in polluting the environment.

The objectives of industrial air pollution control equipment are to:

1) decrease the release of harmful gases and control the spread of air and water pollution

2) Sustainable uses of resources & to conserve natural resources

3) Reduce health threats posed by breathed in and otherwise consumed pollution

Types of air pollution control equipment applied to industrial applications include:

ENERGY SAVING EQUIPMENTS

Many Commercial & Industrial customers reduce energy costs by installing equipments